Sustainable Manufacturing: Why 3D Printing is the Greenest Choice for UAE Industries in 2025

The UAE is committed to net-zero by 2050, and manufacturing has a massive role to play.

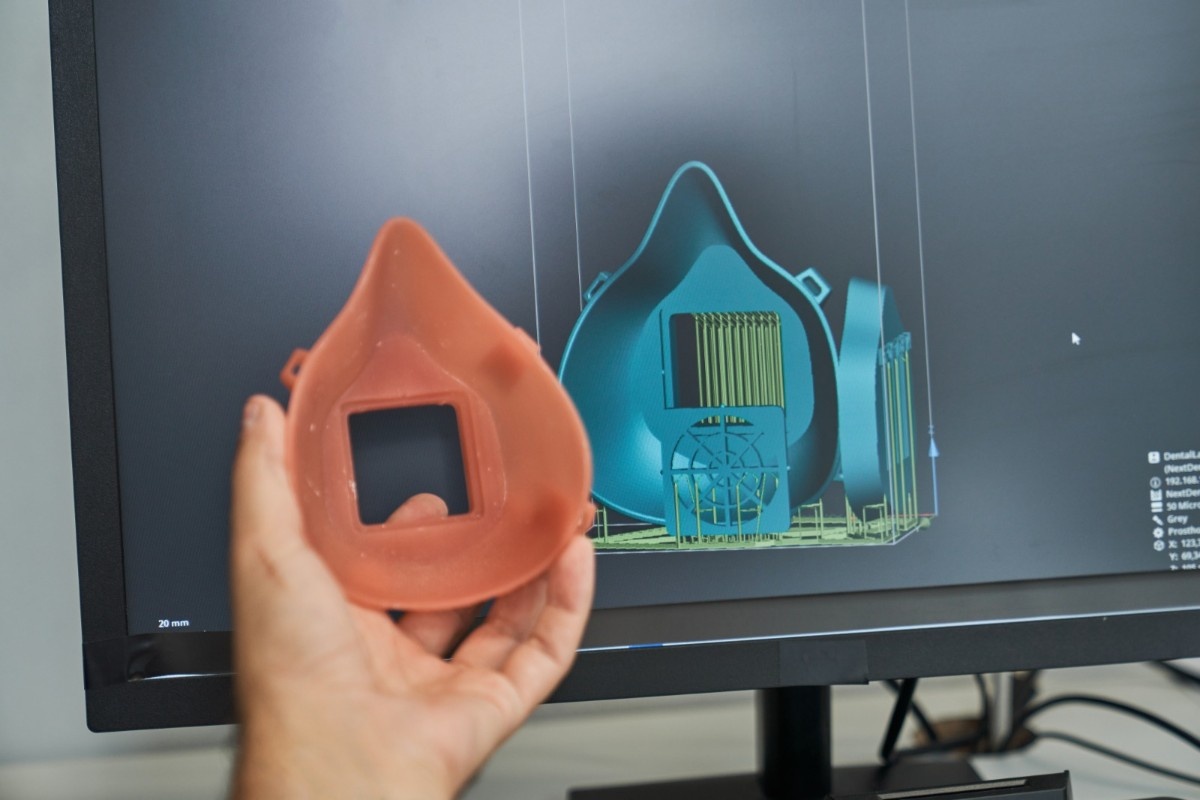

Additive manufacturing is uniquely positioned to help companies meet—and exceed—those sustainability targets while simultaneously improving performance and reducing costs.

Three Ways 3D Printing Dramatically Reduces Environmental Impact

-

Near-Zero Material Waste

Traditional subtractive methods turn expensive blocks of metal or plastic into chips and scrap. Industrial powder-bed technologies (HP MJF & DMLS) use only the material that ends up in the final part—typically 95–98% efficiency. -

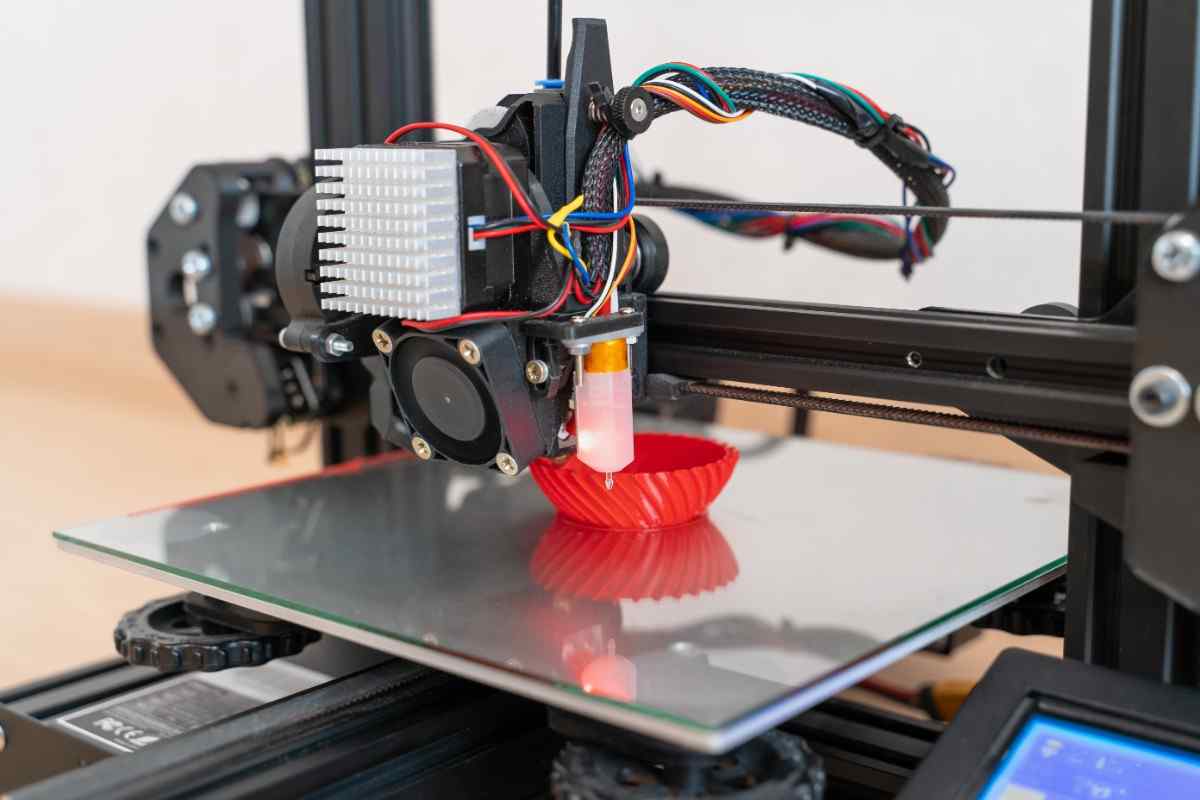

Elimination of International Shipping

Producing locally in Dubai means no air-freighted prototypes from Europe or Asia. For many companies, this single change cuts transport emissions by 70–90%. -

Lightweighting = Lifetime Energy Savings

Topology-optimized and lattice-structured parts can reduce weight by 30–60%. For aerospace, automotive, and robotics applications, this translates into massive fuel/energy savings over the product’s lifetime.

Real Sustainability Wins Already Happening in the UAE

- Oil & gas companies printing lightweight valve components that reduce pumping energy

- Automotive teams using MJF for 40% lighter brackets that improve EV range

- Architecture firms printing scale models with bio-resins instead of machined foam

The result? Lower emissions, lower operating costs, and stronger ESG reporting—all from the same technology that accelerates innovation.

Future-Proof Your Manufacturing Today

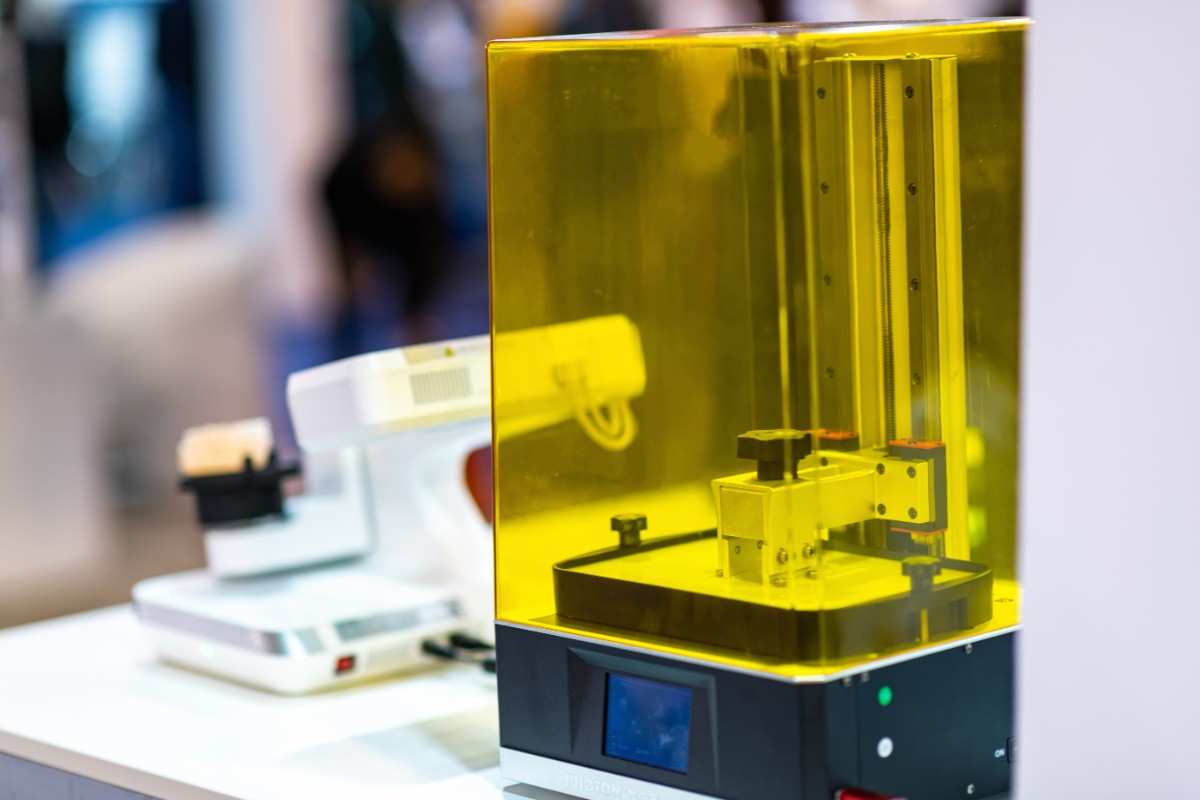

Ultratec 3D is the only ISO 9001-certified facility in the UAE that combines full-scale industrial capacity with genuine sustainability practices—high powder recycling rates, energy-efficient equipment, and local production.

Ready to make your manufacturing greener and more competitive? Let’s discuss your sustainability goals.